Finite element simulation of thermoforming processes for polymer sheets. You can take corrective action at the design or manufacturing phase, or both, to quickly and cost-effectively design lighter packaging with better performance. Your team can improve the quality of blown and thermoformed products by running trial-and-error processes with ANSYS Polyflow, rather than testing changes on the production line. It also produces much of the packaging in use today including blister packs, egg cartons, and food storage containers. Designing equipment and processes for best results involves evaluating multiple designs and optimizing flow and geometric parameters.

| Uploader: | Goltijin |

| Date Added: | 6 November 2016 |

| File Size: | 24.61 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 43977 |

| Price: | Free* [*Free Regsitration Required] |

ANSYS POLYFLOW Software, Computational Fluid Dynamics, CFD, polymer, extrusion

Fluid-Structure Interaction Polyflow includes native fluid—structure interaction FSI to model thermomechanical interactions between flowing materials and surrounding solids in a fully coupled approach. By means of experimental data it is found that modelling of the phase trans As a result, they are able to: We present a numerical simulation for the blow molding of an industrial high density polyethylene part.

Using the data sftware ANSYS explicit dynamics tools, you can conduct virtual drop tests and calculate top-loading deformation. ANSYS Polyflow Capabilities Develop Better Packaging Packaging is important to protect products from damage — but it is also a sustainability issue, as well as an additional cost to goods suppliers.

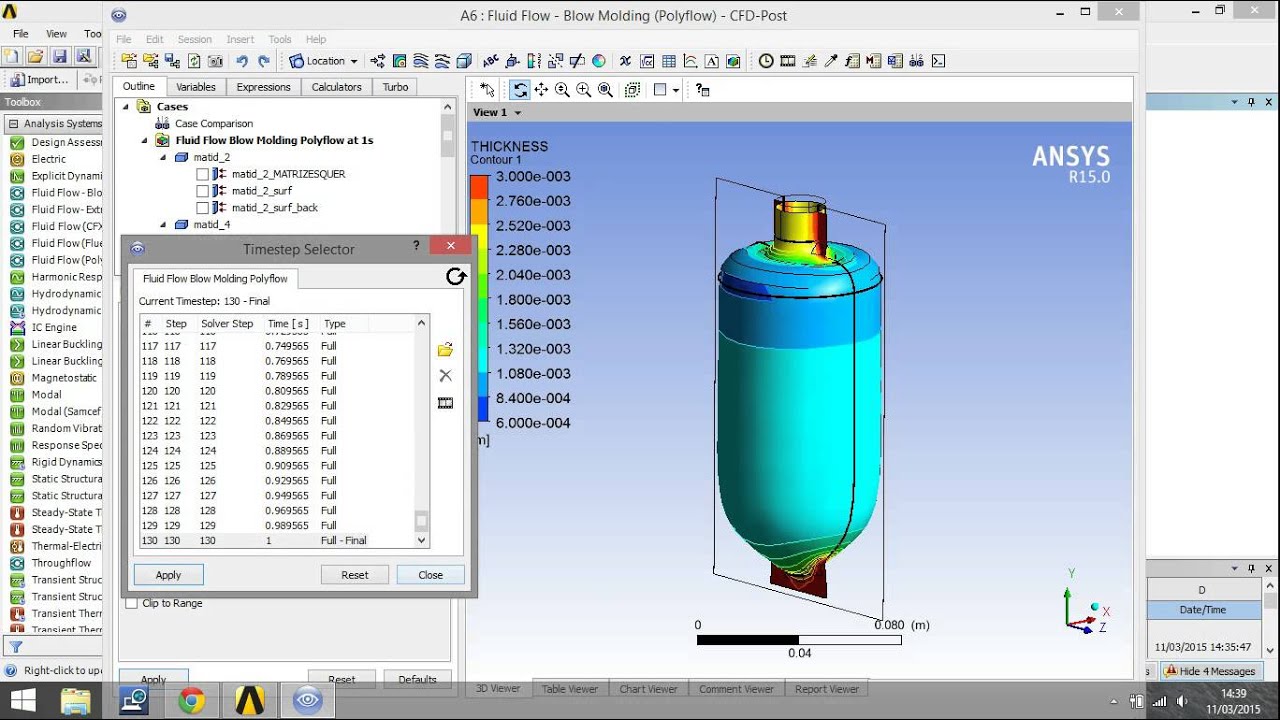

Selected aspects of virtual prototyping the blowing preform process in the ansys-polyflow software. The rheology of the polymeric material is described by means of an integral viscoelastic fluid model with a multi-mode relaxation polyrlow.

Klein 1 Estimated H-index: Industrial thermoforming simulation of automotive fuel tanks. Today this process is used for industrial products including signage, housings, and hot tubs. Thermoplastic sheet is modelled according to the membrane formulation.

POLYFLOW Software

It describes deformation process of a prestretched sheet at any phase of vacuum thermoforming process. By reducing the number of trial-and-error prototypes, simulation can save hundreds of thousands of dollars annually in designing PVC extrusion dies.

A fluid membrane element is presented for the blow moulding simulation of a geometrically complex gas tank. The problem of modelling and the finite element simulation of thermoforming processes for polymeric sheets at various temperatures and for different loading softwarw is addressed.

See how our customers are using our software: The radiative and conductive heat transfer during the reheat stage, the deformation and stress behaviour during the forming stage, and the final cooling stage are simulated. It has shown a good agreement of the deformation profi le with the experimental results.

POLYFLOW Software

The contact between parison and mould is handled by a robust algorithm which is also applied to moving moulds, for capturing the pinch-off. A Lagrangian formulation of the equations polyfow used. Modeling of deformation processes in vacuum thermoforming for a preliminary stretched thermoplastic sheet plug-assist vacuum thermoforming is investigated in this paper.

This process has many advantages over other methods of producing these products, but it has some limitati Polyflow Screw Modeling - Webinar.

Simulation enables you to test the ability to process new resins, even before they have ever been produced, by comparing prototypes for different materials to see if they match or outperform existing and competitive materials. Polyflow includes a vast library of mathematical material models that aid in simulating materials so you can understand and accurately characterize material behavior.

The results of computer simulation of thermoforming process made using ANSYS Polyflow software are presented in this paper. You can reverse-design a resin to maximize end-product performance while minimizing costs and environmental impact.

You can significantly reduce time to market by seamlessly exporting Polyflow results to ANSYS Mechanical softare to perform structural analysis. The most important developments and pokyflow encountered in the thermoforming of polymeric materials have been presented based on a comprehensive review of the literature. Watch Polyflow in Action. Published on May 1, in Polyflkw 1. When large deformations occur within the elastic zone, the mesh resolution is automatically refined to improve the quality of results.

A membrane element is applied for performing the blow molding simulation of polyf,ow complex objects such as a bottle with a handle; the motion governing equations are softaare by means of a Lagrangian representation.

The results of the most recent studies presented in publications related to thermoforming such a Warby 11 Estimated H-index:

Комментариев нет:

Отправить комментарий